Plastic Injection Molding Machine - Blog

You can buy extrusion blowing molding machines, custom extrusion blowmoulding solution, buy extrusion blow molding production line from Sino Holding Group.

Tag: Buy extrusion blowing molding machinesextrusion blowing equipment suppliercustom extrusion blow moulding solutionextrusion blow moulding machines Chinaextrusion blow moulding producing line

Maintenance to injection molding machine is very important, as injection machine clamping units always under high pressure and high speed, so proper adjustment and preventive maintenance is very important to prolong the machine life.

1. Maintenance to machine moving parts

Machine moving plate under high speed movement, so we should do good lubrication between the plate and tie bar. For the machine clamping unit with toggle link structure, the toggle always under movement, good lubrication can avoid damage. If machine stop work, the clamping unit cannot be closed under high pressure for long time, to avoid the broken of toggle.

2. Maintenance to the surface of clamping plate

Machine clamping plate always have high requirement on tooling precision and surface finish. It is an important loop to ensure machine life. Before installation the mould on machine, generally, it needs to paint some oil on the clamping plate to avoid oxidation and corrosion. As to mould, the surface which attaché to machine must smooth, it can ensure good clamping and avoid damage of the mould and machine. Besides, the fix screw and other fix parts should be checked carefully, it must suitable for the machine.

Dakumar Machine not only offer you good machine, also offer you the training how to do good maintenance of machine, any plan to buy new machine, feel free to contact me.

E-mail: export02@sinogroupe.com

Skype: sino-mould-08

Tag: Injection machine maintenanceinjection machine clamping unitsmachine clamping units preventive maintenanceinjection machine running conditionplastic machine clamping units maintenance

Dakumar machinery Co., Ltd invested amount of money to research and develop a new model for injection molding machine—hybrid injection machine.5H injection machine means: high speed; high safety; high injection precision; high energy saving; high stability circulation ability.

high speed:hybrid injection machine adopts accumulator to realize high speed injection, the max injection speed can reach 300-450mm/sec (according to different machine mode)

high safety: Security module independently controlling, it make sure that there is no problem in machine closing, injection, charging, nozzle forward to avoid any accidents.

high energy saving: hybrid injection machine with high response servo system, machine output according to actual need, no overflow no waste; it can save power around 30-70%.

high stability circulation ability:hybrid machine adopts fully closed loop injection system with precision Moog servo valve, make sure injection its’ accurate and stable

Also SINO Holdings built a new factory for our hybrid injection machines.

E-mail: export02@sinogroupe.com

Skype: sino-mould-08

Tag: high speed injection machinehybrid injection moulding solutionH5 injection machineinjection machine in Chinahigh precision injection machinehigh energy saving injection machine

Bakelite molding machine supplier

Tag: bakelite handlebakelite c-type handleindustrial sealsrubber productsBMC productsdiaphragm plate & star cupling

Medical machine solution:

should meet requirements of highly cleanliness

short injecting cycle time, enhance production efficiency

stable operating, make sure medical parts’ high precision and quality

servo control system, max. reduce power consumption, thus lower investment cost

If you have any question, feel free to contact me.

Ms Lucia

Mail: plastic@sinogroupe.com

Skype: sinogroup-11

Tag: medical moldingmedical injection mold machinebuy medical machinemedical making machinemedical injection machinery

China mould company is a famous company with many sets of high precision tooling machine,we could offer you a tunkey solution for the injection molding line,such as thinwall molding line,crate molding line.We have the high precision milling machine from Italy Fidia,Wire cutting machine from Japan,CNC milling machine from Taiwan and so on.

For the high precision milling machine,it is suitable for tooling high requirement steel parts,such as thinwall moulds,electrical part moulds,lighting system moulds.We have two types high speed milling machine in our workshop,one is five axis,one is three axis precision milling machine.

For the precision lathing machine,it is suitable for round parts,such as preform mould,cap moulds,round thinwall container moulds and so on.Sino Mould China could offer you high quality moulds with advanced design,high quality steel material with advanced tooling machines.

Post by Miss Celina

Email: export1@sino-mould.net

Skype: sinomould.dakumar7

MSN: sinoauto@live.cn

Tag: high speed milling machinehigh speed engraving machinecrate moulds toolingthinwall mould toolinghigh quality steel material supplier

The world economy is growing again, the effects of the global economic crisis have basically been overcome. There are clear signs of recovery in every sector of the economy, and in particular in the plastics and rubber market.

INTERPLASTICA Russia will held during Jan.29th to Feb. 1st 2013 in Moscow expocentr Krasnaya Presnya. This plastic trade fair will held once a year, and now it has become the largest plastic and rubber industry trade fair of Russia.

Sino Holdings Group will attend INTERPLASTICA, we will display the new developed hybrid injection machine and thin wall container mould. The machine is fully high speed injection machine can reach a cycle time to 4 seconds.

Miss Rita

email: service9@dakumar.com

skype: sino.group06

TEL: 86 576 81106892

Tag: Russia plastic exhibitionRussia INTERPLASTIC 2013plastic exhibition in RussiaMoscow plastic trade fair2013 plastic trade show

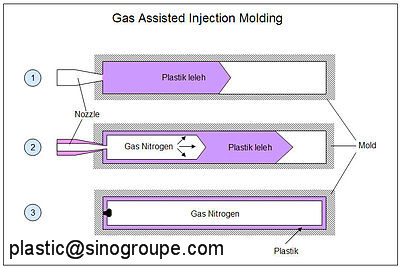

Gas assisted molding solution:

Shorter injecting cycle time. As less material used, less cycle time and cooling cost of plastic parts.

Lower clamping force. Plastic parts can have different thickness by adjusting pressure of air blowing.

Strictly control blowing time and pressure of air system.

If too early, easy to cause part’s break; if too late, will be not easy to blow as material has already been curing.

Better to have pattern on parts, as to cover rough appearance.

Ms Lucia

Mail: plastic@sinogroupe.com

Skype: sinogroup-11

Tag: gas assist moldinggas assist injection moldinggas assisted mouldinggas assisted mould solutioncustom gas assist mold

There are lots injection molding machine manufacturers all over the world and some world famous brand like Engel, BOY, battenfeld, Demag, KRAUSSMAFFEI, ARBURG, NISSEI, BMB, NETSTAL, NEGRI BOSSI… they are with good quality and good service but the problem is their price is also high, not all manufacturers can afford some good machine, and not all products needs such high quality machine. So the most suitable machine is the best.

In China, there are lots machine manufactories, even their quality is not as good as above world famous brand machine, but it can use to make production for some common use products and it can realize its value.

Of course, price is not the only point when purchase the machine, if the machine with very low price, but its quality is very bad, it can only use for one year or less, it’s not a good choice.

How to find machine manufacturer with competitive price in China?

Dakumar Machinery will be one of your good choices. Dakumar machine have been in injection molding machine industry for decades years. our machine price is very competitive according to machine quality, if you want to learn more information about our machine, feel free to send your inquiry to me.

Posted by Elaine

E-mail: dakumar8@gmail.com

Tag: competitive injection machine price offerfactory with competitive injection machine priceChinese injection machine with competitive priceinjection machine with competitive priceinjection plastic machine with competitive price

Assistant machine china supplier

Assistant machine china supplier

And we could also offer you fast delivery time injection machine,if you would like to buy machine quickly from China,please feel free to contact me!

Contact person:Ally

Skype:sino.group10

E-mail:service19@sinomould.com

Tag: Buy machine quickly from ChinaAuto loader supplyair compressor machine supplyShort delivery time assistant machinefast delivery time injection machine

Zhejiang has a long history for plastic mould injection molding machine development, and has gathered many famous injection machine manufacturer, plastic molding machine supplier, injection moulding machine making company. Many customers are going to buy injection machine from Zhejiang.

You may very familiar with famous Zhejiang injection machine brand, such like Haitai, Dakumar, Tongyong, Tederic, etc. Especially for Dakumar Machinery Co.,Ltd, he is a rapid extending Zhejiang injection machine manufacturer. In order to offer better after sales service to over world customers, Dakumar has established machine agents in Turkey, Mexico, Syria, Belarus, etc. And Dakumar have a special team fly over world to offer machine assembling, training, even help customer establish new plastic company in foreign country.

If you plan to visit China and buy injection machine from Zhejiang, you should come to see Dakumar Machinery, which located in Huangyan, Zhejiang province.

Post by Miss Summer

Sino Holdings Group

MSN: sino-mould02@hotmail.com Skype:sino-mould02

Web: www.cnmould.com www.sinomould.com www.dakumar.com

Email: export23@cnmould.com marketing@dakumar.com

Tag: custom injection molding machine from Zhejiangorder injection machine in ZhejiangZhejiang injection machine manufacturerZhejiang molding machine makerbuy molding machine from Zhejiang

Are you looking for plastic injection molding machine? Are you looking for a good long term injection molding machine supplier?

Same as horizontal injection machine, vertical injection is also made by injection system, clamp system, hydraulic system, electric control system, heating and cooling system, lubricate system and safety system.

Compared with horizontal injection molding machine, vertical is suitable for molding some small parts, inserts, plugs, etc.

Vertical injection machine can be divided into four categories:

1- up-right series: is suitable for manufacturing all kinds of connection lines, electronical products, computer data line, etc. it is mainly injection with PVC, PE material, and this series machine clamping force ranges from 15T to 35T.

2- verticalhorizontal series: it is also called C type injection machine. This kind of machine locking mould upright, and horizontal injection without guid pin, so the clamping area form like an “C”, so it is named C type machine.

3- Vertical single return board/double return board series: it is suitable for making high precision parts.

4- Vertical dial type/rotary series: this kind of machine is the best solution for precision insert molding, is suitable for some complex insert molding.

Miss Rita

Email: service9@dakumar.com

skype: sino.group06

Tel: +86 576 81106892

Tag: vertical injection molding machinevertical injectionsmall part moldinginsert moldingelectrical part molding