Plastic Injection Molding Machine - Blog

Dukamar Machinery Co.,Ltd located in Huangyan, Taizhou, which named “Town of plastic mould.”It's one of subsidiary of Sino Holdings Group. Differentinjection molding machines suit for different sizes of injection mould, we have a completely specification of injection molding machine to suit for different kind of mould. We are injection molding machine supplier, injection molding machine maker and offer specification of injection molding machines.

our company has several injection molding machines, they are :

High speed injection molding machine

Variable injection molding machine

Standard injection molding machine

Servo power saveinjection molding machine

Double color injection molding machine

PET&PVC injection molding machine

……..

we manufacture these injection molding machines by ourselves, we have a professional “R&D”team of improving the injection molding machine all the time, we keep improving the theory of working of the injection molding machine, low voice, energy saving, environment production, water and power saving, oil saving. Our injection molding machine series has the highest cost performance among the industry, with high speed and stable working, it suits to various of plastic injection molding.

We can also give you 100% after sales services, During the 1 year guarantee time, Dakumar plastic moulding machine offer all the damaged parts free of charge and response to parts assembling. If the plastic moulding machine out of guarantee time, Dakumarplastic moulding machine keep on offering very prompt service, especially in the area which have set up the service center.

If you are interested in our injection molding machines, ple feel free to contact me. Your inquiry will be grateful. Welcome your down visit.

E-mail: export02@sinogroupe.com

Skype: sino-mould-08

Tag: Injection Molding Machine Company Chinainjection molding machine supplierspecification of injection molding machineinjection molding machine factoryhow to maintain injection molding machine well

What is over molding system? It means product is injected by two different kind raw materials, the material can be plastic & plastic, or plastic & rubber. It is different from double color injection molding.

By double color molding, product can be finished manufacturing on one bi-color injection machine by rotating the moulds. Although over molding needs labor works, it has its own advantages.

Over molding solution:

1) product with better performance

2) lower investment cost, can use virgin material together with recycled material.

3) high requirement of injecting capacity and speed,

otherwise, may cause different thickness of plastic part

Ms Lucia

Mail: plastic@sinogroupe.com

Skype: sinogroup-11

Tag: over molding systemovermolding Turnkey serviceplastic overmoldingover molding china makerover molded china

overmolding injection solution

overmolding is sometimes called insert molding. Regarding mold and machinery, thebi-injection techniqueis the simplest variant of multicomponentinjection molding. Multicomponent injection moldingprocess is the materials are injected simultaneously into the cavity through different gates in a one-step process.

Overmolding injection will reduce production labor cost with fasteners or adhesives. Overmolding injection can also increase the performance of the finished products.

E-mail: export02@sinogroupe.com

Skype: sino-mould-08

Tag: bi-injection techniqueovermolding solutionmulticomponent injection moldingmulticomponent injection molding processsandwich injection molding

Tag: واحد تزریق جت دو رنگی مخلوطواحد تزریق جت تشکیل دهنده که بار اساس قالب گیری چرخشی اتوماتیک عمل کردهتزریق دستگاه قالب گیریدو رنگ قالب گیری تزریقی

As plastic injection moldingis gradually mature understood by more and more people, also various injection molding machine brands explod in nowadays machinery market. Thus used injection machine is becoming a trend.

First is easier to change another brand injection machine. Type of injection machine is still increasing, people is also looking for advantage ones. Used injection machine is the good choice. We can have the machine test to know how quality this brand machine is. If this machine with bad quality, thus we didn't spend too much money on it, it doesn't cause too much waste.

Second is saving money, itis very economical. not like worned-out old machine. Because of rapid increasing new machines, it's price is differ much from the new one, even it only used several months. Thus it is prefered by more and more people.

As we know even used machines, European machine price is high. But we want competitive price but high quality, try Dakumar. Dakumar Machinery offers different types injection machines in China. All related spare parts use famous brand parts, but our price is more preferable for customers.

E-mail: export02@sinogroupe.com

Skype: sino-mould-08

Tag: used injection machine supplyused plastic machinery chinainjection machinery manufacturersecond hand molding machineused plastic molding equipments

As you buy an injection machine China, you will find the famous injection machine China brand or the professional injection machine China manufacturer. Hear, DKM notes you which brand is the best for injection machine China?

When we talk with clients, most of the client will say, pls tell me which brand of the injection machine China is the best? We will say we will offer you the most suitable injection machine China as your requirements. To my opinion, the best injection machine China, the most professional injection machine China maker is not only the best brand injection machine China for the clients, but also can offer the perfect solution to client’s project. We should calculate the input of purchasing an injection machine China, According to their product’s planned profit, to maximize profit and minimize the cost.

The following the best brand of injection machine China for your reference.

HAITIAN injection machine China,

ChenHsong injection machine China,

YIZUMI injection machine China,

BORCHE injection machine China

YILIDA injection machine China,

KAIMING injection machine China

Dakumar injection machine China.

There are still some foreign brands of injection machine made in China or have the branch company in China, like Apollo injection machine ,Sodick injection machine and so on.

Dakumar Machinery is one of the best injection machine China maker, we devote ourselves to offer customers a fine solutions. What the customer bring back is not just an injection machine China, but a perfect service from China.

Post by Miss Joyce ![]()

Email: sino1503@sinomould.com Msn: sinomould-11@hotmail.com

Tag: professional injection machine manufacturerfamous injection machine China brandmaking injection machine Chinasupply injection machine ChinaChina injection machine making factory

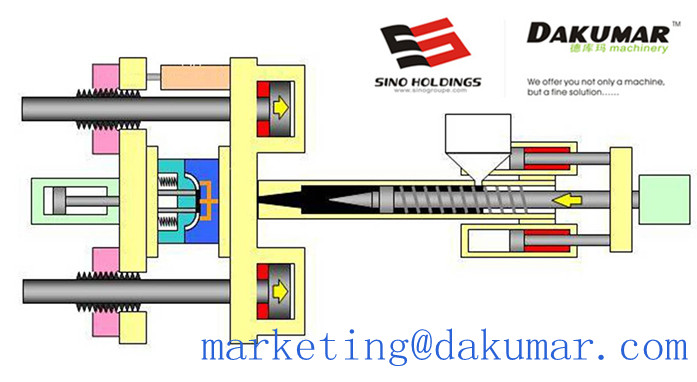

Injection molding machine working principle is similar to the Syringe. Learning injection moulding machine working principle will be great helpful to the production. Injection moulding machines working principle is make full use of thermoplasticity.

After the plastic heated and melting, injection molding machine inject with high pressure to push the plastic flow in the mould, then holding the pressure and cooling, various kinds of plastic products was made by the injection molding machine working together with plastic moulds. Injection molding is a circle progress, every circle main include: ration load plastic, melting, pressure and inject, cooling, demolding. After pick out the product, mould close and entering another circle.

If you want to be a good plastic goods manufacturer, you should learn some basic injection molding machine working principle. If you have any question about machine working principle, please contact me. Dakumar Machinery Co.,ltd is a professional injection molding machine manufacturer in China.

Miss Summer

Skype: sino-mould02

MSN: sino-mould02@hotmail.com

Mail: sinomould02@hotmail.commarketing@dakumar.com

Web: http://www.cnmould.com

Tag: injection machine work principlemolding machine working principleworking principle of injection moulding machineinjection moulding machine operating principleOperation theory of molding machine

High speed hydraulic machine

Nowadays, many kind of injection molding machines are on the market. Customers are dazzled to choose the model of the machine.

Surprise! We are China injection machine manufacturer.Our company Dakumar machinery create a new machine, high speed hydraulic machine.

High speed hydraulic machine’s advantage is short cycle time, save energy, save material, save the wall thickness of the plastic product.

It has a accumulator. This accumulator could make injection better.

The high speed hydraulic machine adopt single hydraulic cylinder structure, the advantage of single hydraulic cylinder is it just have one plunger, and the plunger is light than the standard plunger. And single hydraulic cylinder is more suitable for high speed ejection.

The screw has double thread, the advantage is efficiently.It could mixing and send the material to the charging barrel.

The high speed hydraulic machine adopt servo dynamo to adjust the revolving speed 0-2000r/min. The standard dynamo’s feature is ,the hydraulic pump’s speed could not adjust, 1500r/min.

And our high speed hydraulic machine with fast delivery time, good quality. If you would like to buy machine quickly from China, please feel free to contact me!

Contact person: Ally

Skype:sino.group10

E-mail:service19@sinomould.com

Tag: china injection machine manufacturerfast delivery time hydraulic machinehighspeed hydraulic machinegood quality hydraulic injection machineBuy machine quickly from China

Dakumar is the named-brand plastic injection machinemanufacturer China, famous plastic injection machine seller,high qualified plastic injection machine exporter,high speed plastic injection machine supplier, and plastic injection machine maker,not only offer best plastic injection machine, but also supply the best plastic injection molding service, and provide professional plastic injection molding production line as client’s requirements.

As a plastic injection machine maker China, we should know which points customer cares more about as they want to buy a plastic injection machine.

We will take two kinds of situations into consideration.

One , A fresher wants to start a new plastic molding company.

Our solution: One stop service(Injection molding turnkey project)

know more about information about the product that client want to make, suggestinjection mould maker(Sino Mould Co.,Ltd) ,choose plastic injection machine size, and note Purchasing Dpt to enquiry the auxiliary machines related to the plastic injection machine.

Two, just need plastic injection machine

Our solution: Supply plastic injection machine

We firstly need to get the mould information, and choose a suitable plastic injection machine.

The plastic injection mould size and structure, product weight, plastic materials will decide which type of plastic injection machine is the most suitable for the moulds.

Dakumar Machinery is the China plastic injection machine making factory, is a famous plastic injection machine seller,high qualified plastic injection machine exporter,and high speed plastic injection machine supplier.During the time of offering plastic injection machine, we still offer the customer with all-around sales service to the customers.

If you have the plan for plastic injection machine,or want to know more about DKM, pls contact me.

Post by Miss Joyce ![]()

Msn: sinomould-11@hotmail.com Email: sino1503@dakumar.com

Tag: Plastic injection machine supplierplastic injection machine sellerplastic injection machine exporterplastic injection machine makerplastic injection machine sales service

China injection machine supplier

E-mail: export02@sinogroupe.com

Skype: sino-mould-08

Tag: high speed injection machineBuy injection machine from Chinesetop quality injection machine chinashort delivery time injection machineInjecton machine production line

IML (in mold labeling) technology, nowadays is rapidly developing. What isin mold labeling? What's the advantage of IML(in mold labeling) system?

Turnkey IML project includes plastic mould, injection molding machine, auxiliary machines, robot and labels.

Labels should be the same material as plastic product, when the mould open, at the same time robot pick up the label and put it into the mould before plastic material injecting. Thus IML system greatly enhances product output.

Dakumar Machineryhas rich experience in turnkey IML project, including food container, paint bucket, plastic hanger, plastic chair, etc.

Turnkey IML machine for 400ml 2 cavity food container, side enter robot with DKM 330T, output at least can be around 1500pcs per hour.

Turnkey IML machine for 20L paint bucket, top enter robot with DKM 650T, cycle time can be around 30s. It also can be exchanged for 19L.

Turnkey IML machinefor plastic chair, top enter robot with DKM 780T, cycle time can be around 50s.

Now world economy is recovering slowly, if you have any new project, it's better to start now. Otherwise, you may be behind than others.

We'll sure offer you all related services.

Tag: turnkey IML equipmentturnkey IML systemIML plastic molding serviceIML molding equipmentsin mold labeling service china

Tag: دو رنگ قالب گیری تزریقیماشین جت دو رنگی مخلوطماشین جت تشکیل دهنده که بابر اساس قالب گیری چرخشی اتوماتیک عمل کرده