Plastic Injection Molding Machine - Blog

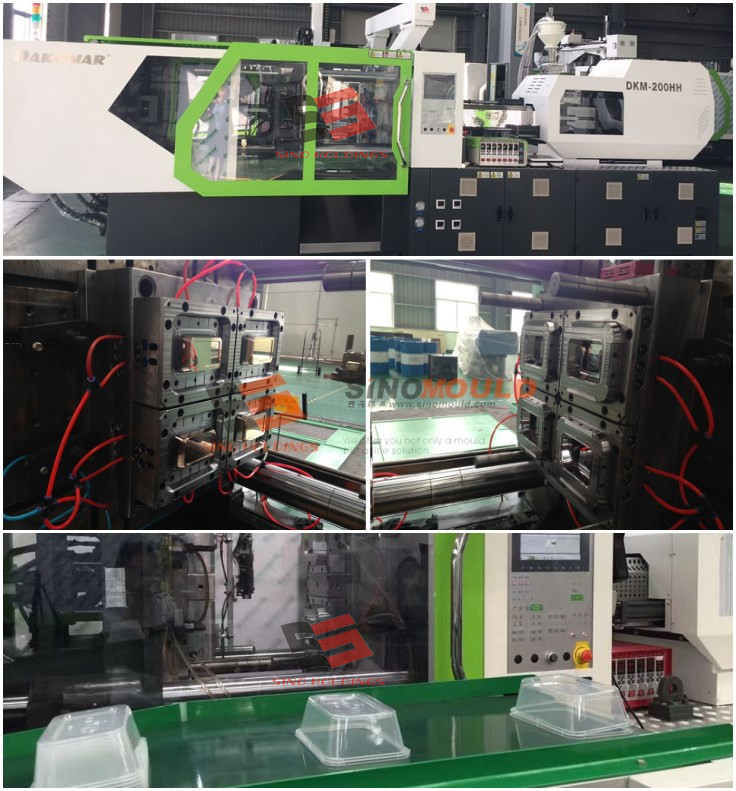

SINO HOLDINGS GROUP is a professional thinwall food container production line supplier.We have gathered rich experience in thinwall food container molding solution, assist our customer establishing their company from zero.

we can offer customer with

-thinwall molding line budget analysis.

-all thinwall molding equipments, customized thinwall mold, suitable thinwall molding machines,

-all necessary auxiliary machines.

-after sale service, like engineering, machine installation, traing on spot support.

-some necessary technial drawings, like your plant water/air/electrical design and lay out.

Regarding the thinwall molding machine, which designed with accumulator to realize high speed injection. Besides, It has the function of 3 axis to realize material charging, mould opening and ejection at the same time. Main application:IML molding with robot system, thinwall container molding , such as ice cream box, yogurt box , disposable food container ect, cycle time can reach 4.0s for 4 cavity ice cream box mould with 0.4mm thickness.

Regarding the thinwall mold,the products are on the appearance of the higher requirements; the surface of the product requires high brightness, so the choice of steel is very important. We generally choose S136 , but considerate the price, we will usually choose DIN1.2738 too.

If you have any new project about thinwall food container production line, please contact us, we will offer the whole turnkey production line for you.

Miya Qiu

E-mail: service7@sinomould.com

whatsapp: 008615712676816

Skype: sino mould –Miya

Zhejiang Dakumar Machinery Co., Ltd is one of most famous Chinese injection molding machine Manufacturer, Trader, Supplier & Importer offering various injection molding machines, like double color injection molding machine, PET injection molding machine, PVC injection molding machine, high speed injection molding machine and so on. Among these machines, we do best in energy saving injection molding machine, which also named servo motor injection molding machine. Below are short introduction of such machine, for your reference.

1. High energy savings: under normal operating conditions, compared with common hydraulic injection molding machines, energy savings of 20-80% can be achieved.

2. Quick operation: the machine runs at much lower noise levels, particularly in low speed applications.

3 Mould stability: compared with conventional injection molding machines, repeatability is greatly improved due to servo motor closed-loop control.

4. Quick response: featuring a dynamic servo motor with a response time of only 0.05second.

5. Reliable holding pressure: compared with traditional hydraulic machine the holding pressure is more stable and does not have limitation.

6. Better oil temperature stability: the servo system only delivers hydraulic oil as it is needed for the various functions. This prevents unnecessary generation of heat and substantially reduces oil cooling requirements.

7. High precision: the machine is applied with Mirle or Techmation control system and Yuken valve, which enable it to control each shot precisely on weight and position and reduce errors in molding tolerance to get high precision molding.

Energy saving injection molding machine can reduce production cost and improve control precision of speed and pressure control. It is suitable for many products, like industrial containers, pallets, chairs, tables,automotive parts etc. We can also offer customized machine according to your requirements. So if you need injection molding machine to realize mass production, please kindly contact me, I willoffer best solution for you.

Post by Miss Mandy

Email: auto@sinomould.com

Skype: sino.mould

Our company is located in world famous injection molds town, Huangyan, taizhou, China. We mainly engage in helping customer establish their plastic injection molding factory. Until now we had set up 608 factories for the customer from all over the world. Among all the production lines, home appliance are the most popular one since home appliance products are selling in very country and every super market in every day.

Plastic home appliance molding factory includes many types, like chair molding factory, table molding factory, basket molding factory, air conditioner molding factory and so on. So most customer enquiry the whole home appliance production line since they want to produce all the home appliance products. However, they do not know the budget for the whole production line can not imagine. Under these conditions, our sales engineer will help customer analysis their market to choose one or two best selling and potential products. Then based these one or two products, we will offer the whole production solution for them and calculate the cost for each finished product to let them know when their can earn back the investment and start to make profit.

Once the customer place order to us, we will start mold, injection machine and necessary auxiliaries production. At the same time, we will invite their one or two engineers come to our company to learn technical points. What’s more, when all the equipment arrive customer factory, our engineers will fly to their factory to do commission and training to make sure the whole production line can run smoothly in customer’s factory.

Pls kindly remember SINO service- mold making, machine manufacturing, automation setup and technical service and training. 2017, we will keep moving! Sino team will always together with you!

Post by Miss Mandy

Email: auto@sinomould.com

Skype: sino.mould

We are China horizontal injection moldingmachine supplier with more than 20 year experience. We are offering wide range horizontal plastic injection molding machine, these horizontal injectionmolding machine are demanded in plastic industry to manufacture different products,such as plastic pallet, plastic bottle caps, plastic auto parts and PCV pipefitting. Offered molding machine is checked on several parameters so as todispatch a flawless range from our end.

We sell our machines in global market within definite time and at affordableprices, with following specifications:

1.High performance energy savingto reduce production cost.

2.High stiffness platen designwith large mold mounting area.

3.High molding stability byadopting servo motor closed-loop control.

4.High efficiency, lower oiltemperature, making oil tank much smaller.

5.Heavy toggle mechanism withlarge mold opening stroke.

6.Injection speed & pressurevariable by hydraulic controls for high quality product.

7.Featuring a dynamic servo motorwith response time of only 0.05sec.

8.Auto lubrication

We are keening on R & D for horizontal Injection molding machine highperformance and improvements. If you are looking for Chinese famous injectionmolding machine supplier, pls kindly send enquiry to me, I will quote and offerbest solution for you.

Post by Miss Mandy

Email: service32@dakumar.com

Whatsapp: +15757610702

We are China Best-selling horizontal injection moldingmachine supplier with more than 20 year experience. We are offering wide range horizontal plastic injection molding machine, these horizontal injectionmolding machine are demanded in plastic industry to manufacture different products,such as plastic pallet, plastic bottle caps, plastic auto parts and PCV pipefitting. Offered molding machine is checked on several parameters so as todispatch a flawless range from our end.

We sell our machines in global market within definite time and at affordableprices, with following specifications:

1.High performance energy savingto reduce production cost.

2.High stiffness platen designwith large mold mounting area.

3.High molding stability byadopting servo motor closed-loop control.

4.High efficiency, lower oiltemperature, making oil tank much smaller.

5.Heavy toggle mechanism withlarge mold opening stroke.

6.Injection speed & pressurevariable by hydraulic controls for high quality product.

7.Featuring a dynamic servo motorwith response time of only 0.05sec.

8.Auto lubrication

We are keening on R & D for horizontal Injection molding machine highperformance and improvements. If you are looking for Chinese famous injectionmolding machine supplier, pls kindly send enquiry to me, I will quote and offerbest solution for you.

Post by Miss Mandy

Email: service32@dakumar.com

Whatsapp: +8615757610702

We are appreciated for offering Plastic Injection Molding Machinesand the ranges are available from 50Ton to 4000Ton.These are developed with the help of top notch techniquesand are capable of fastening molds in either a horizontal or vertical position.These are tested on different parameters to suit clients’ requirements. Untilnow we have developed many type machines, like PET machine, PVC machine, highspeed machine, servo motor machine and so on. Among these machines, we do best in servo motor injection molding machine since it can save 20%-80% energy.

achines, we do best in servo motor injection molding machine since it can save20%-80% energy.

Key Features:

1. Saving energy of around 20 to 80% in comparison toconventional hydraulic machines.

2. High-performance servo motor & dynamical controlsystem.

3. Machines designed on platform of latest injection moldingtechnology.

4. All parts are from world famous brand, like computer isKeba from Austria, servo motor is Phase from Italy.

5. High precision and high efficiency

6. Automatic centralized grease lubrication.

7. Stable operations with precision integration of mechanical,hydraulic and electrical units.

8. Lower noise levels.

Above are our servo motor machine advantages, for your reference.

Please kindly note that we are not only servo motor injection molding machine supplier, maker exporter, trader; we arealso plastic production line offer with more than 10 year experience. If youhave any project need injection mold or machine, kindly contact me, I will offerbest solution for you.

Post by Miss Mandy

Email: auto@sinomould.com

Skype: sino.mould

Whatsapp:+8615757610702

Sino Group specialized in offering package production lines,like cap injection molding line, PET preform production line, PET bottleblowing production line, test tube production line, syringe production and soon.

Below is briefly introduction of 500ml PET Water Bottle Production line, production capacity is 3000pcs/hour, for your reference.

1. Injection molds

The whole production line needs at least three tools, 24 cavity 500mlPET preform tool, 16 cavity cap tool, 4 cavity 500ml bottle blowing tool. Ifcustomer wants different bottle shapes, then we can make extra bottle blowingtools.

2. Injection machine and blowing machine

One set DKM268T PET servo motor injection molding machine forpreform molding, one set DKM138T servo motor machine for cap molding, one setfull-automatic blow molding machine for bottle blowing.

3. Injection molding machine optional auxiliary

Robot system

Hopper dryer

Auto loader

Hopper Magnet

Mold clamps

Water cooler & water tank

Plastic dehumanizer

Mold temperature controller

Oil temperature controller

Oil bypass filter

If you have plan to set up packaging molding factory, pls kindly contact us. We will offer one to one sales engineer serviceto help you analysis your project based on your working situation and market.What’s more, when all the goods are reached customer’s factory, we will arrangeour engineer or agent to customer’s factory to do installation and commission.

Post by Miss Mandy

Email: auto@sinomould.com

Skype: sino.mould

Whatsapp: +8615757610702

Paintbucket is widely application in home appliance decoration industry, so itattracts investors to develop on this. SINO MOULD is professional on supplying paintbucket production molding equipment which containspaint bucket mold, injectionmolding machine, robot, and chiller and so on.

Paintbucket mold:

Steel: P20or 718H made in China, which could guarantee at least 1M shots.

Injectiongate: Hot runner system, Anloe brand

Ejectiongate: stripper way

CavitiesNo: 1 cavity

Structure:with optimal cooling system and air venting system.

Precisioncontrol: After each tooling step, we will check dimension by bridge coordinate measuringmachine. Once it passed, then go next step. Besides, our tooling machine hadDMG high speed milling, Japan Shaddic and Japan Marzark high precision lathe.

Paint bucketmolding machine:

Wesuggest using servo motor injection molding machine for producing paint bucketproduction. The advantage is could save 20%-80% energy and with servo motor,action precision could ensure and will get the best injection result. And theservo system compared with traditional machine, its holding pressure is morestable and dwell time is much extended which is better for test tube molding. Besides,dynamic servo motor with a response time of only 0.05sec and machines runs atvery lower noise level and operate stability.

Withhelp of dryer, chiller and others accessories equipment, those will improve cycletime and get the best injection result. What’ more, we had machine agent inJordan, Columbia, South Africa, Nepal, Mexico, Greece, Ukraine and others whichcould provide fast and convenient after-sale service and technicalrecommendation.

If youwant to set up your own paint bucket molding factory, pls kindly contact me,Iam glad to reply you and offer best solution for you.

Post by

Miss Mandy

Email: auto@sinomould.com

Whatsapp:+8615757610702

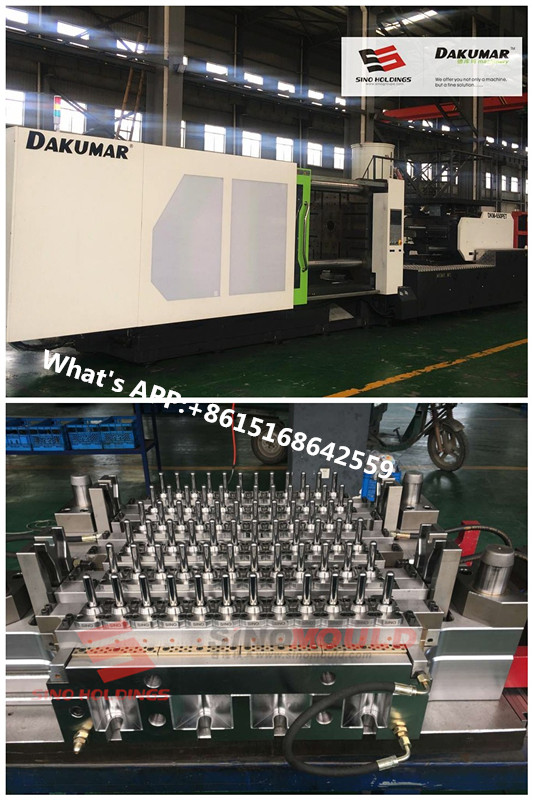

Zhejiang Dakumar machinery Co., LTD specialized in manufacturing pet preform injection molding machine from 1992 and variety from 110 tonnage to 650 tonnage.

To suit PET material property, our molding machines were designed and made which intend to increase plasticization and production ability. So, preform machine screw is custom and special. Not only increase screw diameter and enlarge L/D radio, but also design twin screw which improve preform molding greatly.

A good pet preform injection moulding machine needs showing its stability operation. Our PET machine use servo motor made from PHASE and servo driver made from Inovance. And computer control panel is KEBA brand which is easy and control more precision. Besides, no matter back pressure valve or PQ valve or Eletromagnetic directional Valve, most of valves useYuken from Japan.

What’s more, for high safety protection, preform injection machines were designed with mechanical safety, electronic safety and hydraulic safety. And our moulding machine had already passed CE certification.

Any question regarding to PET preform molding machine or custom pet molding machine, pls feel free to contact my email: sino6001@dakumar.com

Post: Stacy

Skype: sinogroupe-62

What’s APP: +8615168642559

We had already provided many pet bottle factories in Thailand, Spain, Nigeria and others. From PET raw material purchase to all water bottle equipment, we had ability to satisfy each step.

A complete pet water bottle lines contains PET raw material, PET injected mold, PET preform injection molding machine and related accessories, blow mold, blowing machine and filling machines. Below simple introduce our 72 cavities injection pet water line.

Preform is PCO 28mm water 0.5L, gram is about 16g. Since customer per hour capacity need reach about 12,000 pieces, we design preform mold with 72 cavities. And use S136 steel for cavity and core,P20 for mold base. Besides, preform design need special attention on cooling system and air venting system. With rich experience, our team had finished and were successfully proved by actual production operation.

After preform mold finishing, PET injection molding machine is also a main role in water bottle line. Moulding machine requires high plasticization, high gram weight per shot, and stability operation and easy for maintenance. Besides, other accessories like water chiller, dehumidification and dryer machine and so on, this will greatly improve cycle time.

More information regarding to pet bottle factory, pls feel free to contact me.

From : Stacy

Email: sino6001@dakumar.com sino6001@sinomould.com

Skype: sinogroupe-62

What’s APP: +8615168642559

Sino Holdings Group company China is a professional manufacturer for PET preform mould and PET injection molding machines, we could suppply whole PET preform production line service. Our whole line service setup in many different countries in the world, such as Spain, Saudi Arabia, Syria, Algeria, Nigeria, South Africa, Thailand and so on. We could arrange our professional service team to customer factory for machine assembling and staff training.

In Spain, we have setup one PET production line for 90g PET preform, which is suitable for 5L bottle blowing, suitable for food oil containing. The 90g PET preform mould with 16cavity, Mould material is S136 stainless steel, fully-valve gate hot runner system, with optimized cooling system design and high pressure water chiller, the whole PET preform production line would run within 40s.

As a group company, Sino Holdings Group could supply PET preform production line equipment, which have the branch company for Sino Mould and Dakumar, one for plastic injection mould, one for plastic injection molding machine manufacturing, our engineers could work well for both machines and mould maintenance. We have the foreign service team to different countries. If you are new in the plastic injection molding industry, welcome to contact us, we could supply one stop service with technology support. Thanks.

Post by Miss Celina

Skype: sinomould.dakumar7

whatsapp: 008615257606120

email: export07@sinogroupe.com

DKM is a pioneer in the department and innovation of high speed injection molding machines in China.Dakumar high speed injection molding machines are very famous in injection molding machine industry.

The traditional high speed injection machine is focus on the injection speed, which use of accumulate as an injection power source to provide energy for injection., sino holding group R&D5H high speed injection machine on the basis of high-speed injection with two sets of servo hydraulic system, while theoil were action to achieve two-axis or even three-axis.the machine cycle speed, high production efficiency,with a very high price, especially suitable for the production of thinwall food container and high precision products.

About 5H, which include high speed, high efficiency, high safety, high precision, high energy saving.

High speed (high speed response accumulator):Machine adopts accumulator to realize high speed injection ,the max injection speed can reach 300-450 mm/sec.

High efficiency(clamping unit): speed of the Mold clamping is 10%-20% faster. standard machine can realize mold opening and ejector at the same time, it saves cycle time.

High safety (hydraulic unit): security module independent control,it ensures safe machine closing, injection, charging, nozzle forward to machine to avoid any accident. Fully closed machine frame.

High precision (electronically controlled unit):Configure European advanced controller, to precisely control the temperature and location.

High energy saving (injection unit):.with high-response servo system, it can save power by 30%-70%, Reducing the cost for customers to save resources.

Some important parts of our machine are introduced from abroad, for example: the controller is KEBA (made in Austria); the electronic ruler is GEFRAN (made in Italy); the electromagnetic valve is Yuken (made in Japan); the stroke switch is OMRON (made in Japan)etc.

Need further information about high speed injection molding machine? Welcome to contact me.

Miya Qiu

E-mail: servicr7@sinomuld.com

watsapp: 008615712676816

skype: sino mould - Miya