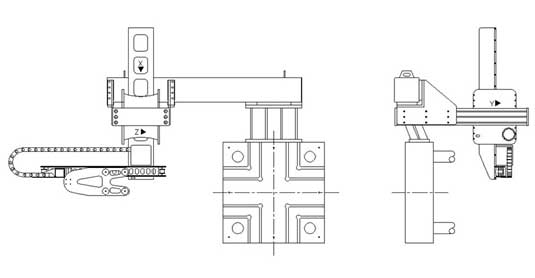

The side entry robots series Side CNC (numerical control) has been designed to satisfy the demands for very high speed cycle and the quickest unloading of the moulded parts. The high rigidity structure combined with very powerful motors. It allows reaching an overall cycle time of 2.5 seconds (stacking inclusive) and a moulding delay time of0.4 second. This series of robot is particularly suitable to be used in the food packaging, in mould labeling (IML), in CD box production, etc... In comparison to other similar robots, this series of robots, being also provided with a third motorized vertical axis which can directly stack the moulded parts without any other external automation. Simple and intuitive programming, without limits! Very practical it is besides the possibility to directly fix the robot on the top of the fixed plane of the injection moulding machine as a traditional robot, in order to avoid encumbrances on the floor and not to have any relative movement between injection moulding machine and robot (however, if required, it is possible to install the robot to a special structure fixed to the floor).

High-power servo motors, digital encoders controlled,

Side entry speed in the mould up to 7.5 meters/sec,

Simultaneous and interpolated axis movements,

Double vacuum circuits,

Rotation wrist of 90°,

Numerous inputs and outputs to converse with external automation.

Free Guided Programming (FGP): it allows to write the work program using ‘actions’ ready to use, contained in a special bookstore,

Keyboard controller remotable with ample colour 8.5” display ‘Touch Screen’,

Self-teaching of the axes positions,

Steep bi steep execution of the work program,

Compact Flash card to save the programs.

| |||||

Robot Type | Suitable Injection Machines | Working Strokes | Max Applicable Weight | Min Cycle Time | Stop Mould Time |

SIDE 1 | 100 ÷ 250 ton | X= 700 mm (vertical) | 4 Kg | 2.5 sec | 0.4 sec |

SIDE 2 | 250 ÷ 400 ton | X= 700 mm (vertical) | 4 Kg | 2.7 sec | 0.4 sec |