Plastic Injection Molding Machine - Blog

Dakumar Machinery supply whole plastic crate production line. For the countries which are rich in fruits, the plastic crates are widely used for fruits shipping, such as India, Thailand, Indonesia,and so on. As a professional manufacturer for plastic crate molding equipment, Dakumar supply high quality plastic crate production solution with technology support.

For the crate injection molding machine, we designed with mould open and ejection could do at the same time, the hydraulic cylinder do action at the same time during mould opening, that could reduce the mould running cycle time for 2s and protect the crate ribs well. According to the crate size and crate mould cavity number, we could suggest suitable Dakumar machine for you. Normally we used DKM650 and DKM850 for popular plastic crate size.

Except plastic crate injection molding machine, we could also supply high quality crate mould, with hot runner system and P20, 718H steel material for the core and cavity, the cooling system for the crate mould is well designed.

If you have new plan to start plastic crate production before the busy seasons coming, welcome to contact us, we could ship the whole crate molding line with injection molding solution. Waiting for your enquiry. Thanks.

Post by Miss Celina

Skype: sinomould.dakumar7

Whatsapp: 008615257606120

Email: export07@sinogroupe.com

DKM is a pioneer in the development and innovation of injection molding machines in china. DKM continuously improve the design, has always been focused on the improvement of thin wall container machine, high speed injection machine system research and development with stability and high precision.

We have high speed model from DKM118 to DKM780, the standard high speed

machine with an accumulator, to achieving high speed rotation of the screw.

According to customer requirements to achieve high speed opening and closing

when themold is working. This series uses a special machine base frame and

mold design.In the past few years, DKM high speed machine in a large and small exhibition athome and abroad, because of high quality and stable performance,

we provide customerswith injection molding machines with a fine solution.

The role of the accumulator is to store the hydraulic oil in the hydraulic system,

when necessary, released.

1.Auxiliary power in a work cycle (or a trip)speed difference is very big, in this system set accumulator, you can use asmaller power pump to reduce the

power of the main drive, So that the entirehy draulic system of small size,

light weight, low prices.

2.Emergency power source

3.Add leak and maintain constant pressure

4.The absorption of hydraulic shock

5.Absorb pulsation, reduce noise

If you have any project need thin wall high speed injection machine, please feel free to contact us.

We will offer you the best solution for your thin wall container molding machine.

Posted by miss Nancy

Skype: sinomould-01

E-mail: sino1105@dakumar.com

WhatsApp: +8613758679372

SINO as a professional injection supplier, since its inception the company has been committed to the design and manufacture of plastic molds and injection moldingone-stop service. We can offer you plastic production line. Until last year we have built 607th factory turnkey projects all over the world.

Let’s show youIML bucket production line, we can offer IML bucket mold with 1L, 2L,4L, 5L, 10L, 12L, 15L, 18L, and 20L.

Belowis all the equipment for IML system:

Injection system:

1. Plastic injection molding machine.

2. Plastic raw material dryer

3. Plastic raw material auto loader.

4. Plastic injection mold

5. Water chillers.

Labeling system:

1. Robot for label collecting.

2. Robot for feed the label into the mold and pick out the plastic labeled parts.

3. Robot for stacking the plastic labeled part.

4. Conveyor

5. Labels.

Mold supplier is SINO-PK, hot runner supplier is Anole hot runner, machine supplieris Dakumar machinery, and robot supplier is DKM robot S.A, Italy.

Usually our delivery time is 45-60 days, it includes 2D/3D plastic design is 2-3 days,2D-3D mold design is 3-4 days, steeling cutting is 5 days, mold make is 35-45days, mold trial and plastic checking is 5-7 days.

Anyneeds for machine or molds, pls feel free to contact us.

Postedby Vicky

Email:service37@sinomould.com

Whatsapp:008615905869677

Skype:sinogroupe-59

Nowadays, more and more families prefer go for a picnic or seaside to enjoy a happy weekend. Drive with a car will be much more convenient to them. So they will bring plastic folding table and chair with the car.Plastic folding table and chair production machine will be very hot in the sooner future. Our sales of quantity keep increasing in the recently years.

As is known to all, folding table and chair can help save too much space for our limited home. We can fold them when they are free. So when we make design of the plastic table and chair, we should pay much attention to the fitting structure.

Dakumar machinery joint Sino mould will offer you a very fine injection molding solution. First, we will help you benefit your old table and chair design to prevent all possible problems which will turn up in the future production or daily using. Second, we have rich experience in plastic table and chair mould design, reasonable mould design with good cooling system, enlarge your year output to realize low input, but high output. Third,Dakumar have machine from 50T to 4600T developed by Italy engineer, suitable injection machine selection is very important to your future production.

Engineer oversea service is available foryou. so there’s no worry about less experience of you. Dakumar engineers will help you install your factory, make training to your workers and offer you good after-sale service in time. Welcome contact me about plastic folding table and chair production machine.

sales engineer: Miss Candy

email: dakumar-sales@dakumar.com

skype: anole-hc-02

whatsapp: 008615858685263

Dakumar Machinery plays a very importantrole in China injection moulding machine field. Dakumar not only supply highspeed injection machine, servo motor injection machine, but also focus on largehydraulic injection machine manufacturing.

Annually, Dakumar machine manufacturingcapacity is over 1000 sets. For popular injection machine model, such like 130ton,250ton, 350 ton, 520 ton, 1150 ton, and 2600 ton, we also preparedready-made machine in stock. The largest machine we can make is 4000 ton. Nowwe have 3350 & 2600 ton machine ready in stock, it is very suitable forproduce industry use pallet, dustbin, tank, etc. Besides, we have a 1500 tonmachine with gas assist chair mould ready for sell. One you make the payment,we can ship machine and moulds immediately to you.

Dakumar large moulding machine is highadvanced injection machine with famous brand Electronic & Electrical Components.The machine controller is KEBA from Austria that most European brand injectionmachine use. The large screen and good look machine design brings very goodoperating experience. For other specification, please check contact DakumarMachinery sales people. We offers customer high quality automatic devices andauxiliary equipment, including auto loader, hopper dryer, water chiller,tooling tower, color mixer, crusher, mould temperature controller, robot,conveyor,etc.

Inquiry email: marketing@sinogroupe.com

skype: sino-mould02

High speedinjection molding is required in many injection molding area. And some plastic injectionmolding supplier could offer high speed injection molding service for clientsnowadays. So what is high speed injection molding? High speed injection moldingis a technology to injection a plastic parts in a short cycle time with itshigh speed injection. In this way, we could get more perfect plastic productsin shorter time comparing with before.

This technology usually used in thin wall production line, airline cap production line, some medicalproduction line, electrical products production line and so on. Because theseproducts have big amount production requirement and do not have high injectiondetails during production, so we could produce it fast and get profit forclients.

SINO HoldingsGroup, one of the famous export for plastic injection molding injection, alsohave almost more than 15 years studying and developing in high speed injectionmolding. We have 5H series injection molding machine are specially developedfor high speed and high precision injection molding. The machine frame,clamping units are much more stronger for high speed and high pressure working,They are stable.

Any interested inour high speed injection molding machine, please feel free to let me know. And welcometo our factory for further discussing.

Snow

Export3@cnmould.com

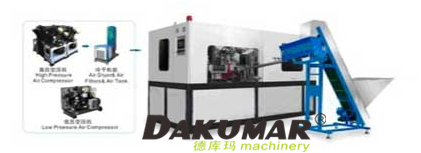

Dakumar machinery is focus on providing customers with the entire line of PET preform solutions.from the design to the beverage packaging preform, with its first-class quality,excellent service to help customers achieve the most economical and reasonableinvestment planning! And Dakumar became known as the most reliable enterpriseis to provide customers with the entire Mineralwater, beverage bottle production line.

However, Dakumar is not satisfied with their achievements, we willcontinue our efforts to improve self quality. make the greatest contribution tothe thriving of the US PET packaging market! Our goal is to enable ourcustomers to maximize the effectiveness of the smallest input!

What equipment do we provide?

1.Tube blank mould

2.- injection molding machines and auxiliary equipment

3.Bottle blowing mould

4.Bottle blowing machine

5.Filling machine

6.Transport system

7.Post packaging system

We are happy to design the most economical solution for you, andplease provide us the following information:

1 please specify the bottle specifications, including bottle shape,volume, weight, diameter, filling temperature, etc..

2 please tell us your packing type. Water, juice or gas?

3 please tell us what you want to achieve per hour.

Ifyou are looking for a full production line ,such as Mineral water, beverage bottle production line. Please feel kindlycontact me :

Posted by: Rose Wang

E-mail:sale66@sinogroupe.com

Whatsapp/tel:+8613738591683

Skype: Sino mould-Rose

Dakumar is one of the world's most famous injection molding machinesuppliers, exporters and manufacturers. We not only provide customers with thin-walled injection molding machine,thin-walled injection molding program, but also to provide our customers withdifferent types of thin-walled injection molding services:

We have a lot of professional engineers,these engineers have a lot of experience in the production of thin-walledinjection molding machine, in particular high-speed machine, according to thehigh-speed thin-walled injection molding technology to provide customers withthin-walled molding program.

Compared with the traditional injectionmolding machine, we have the characteristics of thin-walled injection moldingmachine:

1 high speed

Our machine uses high precision singlecylinder injection molding system, especially suitable for low inertia highspeed injection molding and rapid response speed, thin wall injection moldingmachine can produce more effective production of thin-walled products and saveproduction time.

2 high energy saving

High response servo system of the machine,the machine output according to the actual needs, will not overflow, will notwaste. It can save 30-70% energy. Compared with traditional machines, we useservo motor to save energy and control the position more accurately.

3 high security

Thin wall high speed machine withmechanical, hydraulic, electrical three protection. Independent control of thesecurity module will ensure that the machine is not closed, injection molding,feeding, nozzle, to avoid any accidents.

High speed machine specializes in thedevelopment of high speed and high precision injection molding. High speedmachine frame, clamping device is stronger than. High speed machine is alsostable in high pressure.

This type of high speed injection moldingmachine using high injection speed, shorten the operation cycle time, workefficiency, especially suitable for ultra-thin, high precision and complexproducts.

If you have any items that require a thin-walled injection molding machine,please feel free to contact us. We will provide you with the best thin wallhigh speed machine for you.

Posted by: Rose Wang

E-mail:sale66@sinogroupe.com

Whatsapp/tel:+8613738591683

Skype: Sino mould-Rose

For packaging products molding service, Sino Holdings has more than decades experience with multi-cavity PET preform production lines,72-cavity water cap molding, 48-cavity 5 gallon handles molding and so on. We supply these with tailor made molds, high quality molding machine and additional equipments. No matter, you have packing production line / filling line, or green hand for plastic packaging industry, SINO will be your consultant, partner and supplier.

All packaging molds, we applied S136 stainless or DIN1.2316 stainless for mold cavity insert, core insert and neck screw, which suitable for long time high speed runs stably. We tooling mold spare parts with precision grinding machine and dimension measure up to D-M-E metric standard which are easily for after maintenance.

Our multi-cavity PET preform injections machines are specially designed with customize barrel & screw, plasticizing motor, injection cylinder, electrical machine and controller, tailor manifold ect. Good cooperated with our SINO PET preform molds, our PET molding line runs well and stably to realize your high production quantity. Like 72-cavity 28mm neck PET preform with 25g weight, its cycle time is around 20 seconds on our Dakumar PET machine 650T. If you have new projects to start packing production line, welcome contacts us.

Posted by Ms. Helen

Email: service19@dakumar.com

Cell phone:0086 15858625783

Skype:sino.group10

China plastic injection molding machine supplier Dakumar Machinerysupplying high quality & high speed airline spoon injection molding machine by high speed injection.

To considering maximize capacityfor airline spoon, airline fork, airline knife in very thin and light design, andhigh quantity needed, high speed injection molding machine are necessary for airline,to reach fast cycle time, the characteristics of high speed machine is specialinjection system to reduce machine injection time also precision position,Dakumar machine high speed machine using moog valve for high precisioninjection.

And another important pointfor save time is mold open, eject and charging at same time, common machineopen mold need 2-3s, charging and eject need 3-4s, Dakumar high speed injectionmachine need 3s to finish these three action at same.

For plastic airline spoon in24cavity round mould design cycle time is 8s, the quantity more 200000 per day,help customer rapid recovery cost.

Such as disposable spoon,knife or spoon need high quantity production, high speed injection productionneed good injection machine and also good plastic injection Mould in fastinjection and long Mould life, 50-100K shots. Sino holdings group have plasticMould Company and injection machine manufacturing, many good experiences onplastic injection molding. Welcome contact us if you are find good Airline spoon injection molding machine supplier.

Contact information:

Email: export02@sinogroupe.com

What’s up: 0086 15257606121

We are looking for Dakumar injection machine agent in Algeria, as China famous injection machine manufacturer, subsidiary company of Sino Holdings group--Dakumar machinery could offer you high configuration and high performance injection molding machine with competitive price. Now in order to expand our market in Algeria, we are looking for partner to become our machine agent in Algeria.

We hope our partner is in the field of injection molding, mechanical or mold, who has the ability of Market development, technical support and after-sales service. You may be wondering what I can give you and what you can gain, I will analyze you from three aspects, pls see detail as following:

1.Industryoutlook

Inrecent years, plastic products are more and more widely used in our life, su chas home appliance, daily necessities, chair and table, crate, auto parts, etc. It means that injection mold and injection machine also has such a big demand in the injection molding industry. And now, Algeria's economy is growing fast, industryis in a state of rapid development, at this time, seize the opportunity of the injection molding industry is very favorable.

2.Sino's strength

a) As one of the few turnkey suppliers in China, Sino could offer you injection machine and mould, also necessary devices, if your customer want to buy injection machine or mould or production line, from us, you can got all of this devices.

b) About injection machine, our machine scover servo motor injection machines, standard injection machine, high-speedmachines, bi-color injection machine, PVC/PET injection machine, also, now our Italy CTO and our engineer are developing two platen injection machine, our machine type from 50T to 4600T, it can meet your all kinds of production needs.

3.Sino's supportpolicy.

a) SINO promotion for agent specially internet promotion service

b) Newspaper or yellow page to promote

c) Local exhibition with SINO brand machinesand every year Chinese exhibition invites

d) Sparepart in stock for maintains

e) Commission after you sell injectionmachine, etc.

More info for Dakumar injection machine agent,Welcome to contact me, and welcome Algeria's people with lofty ideals to join us!

Miss.Ysaline

Whatsapp :+ 86 138 5763 5311

Email:export12@sinogroupe.com

Nowadays,the requirements of manufacturers for plastic injection molding machine is growing, the growing competitiveness among suppliers. As a professional machine supplier, Dakumar understand the needs of these manufacturers, we can offer servo energy injection molding machine to meet their needs.

The following are the characteristics of our machine: high energy saving, molding stability, quick response, quiet operation, reliable holding pressure, better oil temperature stability.

Under normal operating conditions, comparedwith conventional hydraulic injection molding machine, servo machine can reduce20-80% energy, repeatability is greatly improved duo to servo motor closed-loopcontrol.

What’s meaning of servo system ?

1.High performance energy savingto reduce cost

2.Not only save energy, but alsorealize the precise speed and pressure control.

3.High efficiency, lower oil temperature, making oil tank much smaller and the service life of hydraulic oil and elements much longer.

During cooling time, the servo motor stops rotating, the system does not consume energy.

During holding pressure, the servo system output little hydraulic oil system to supplement the drain; the consumption point can be very small.

When system is running, the basic no overflow loss, no energy consumption.

There are more advantages for our servo energy injection molding machine.

Any needs, pls feel free to contact us.

Post by Vicky

Email:service37@sinomould.com

Skype: sinogroupe-59

Whatsapp:008615905869677